Maintenance of Weichai Diesel Generating Power Engine

- Jun 14, 2019

- 5 min read

Maintenance of Weichai Diesel Engine

Fuel For summer: 0# diesel (GB252).

For winter: usually use -10# light diesel (GB252). But when barometric temperature is lower than -15°C, use -20# diesel, and when outdoor temperature is lower than -30°C, use -35# diesel.

Note: all the fuel used must comply with specifications in Table D1 of Appendix D in National Standard GB 20891-2007.

Lubricant First-time oil-filling volume for the engine is 9L; however, the capacity of lubricant is based on the mark of dipstick.

Non-road Tier 2 series diesel engines use oil of Grade CF-4, and to choose the viscosity of special oil according to temperature; please refer toTable 4-1.

Note:

1) Before start-up of diesel engine, first check the oil level in the oil sump.

2) Do not check the oil level when the diesel engine is running.

3) The special oil is not allowed to be mixed with any other kind of oil of different quality.

Table 4-1 Corresponding Table of Viscosity and Ambient Temperature

Coolant

The diesel engine cooling system must adopt pure cooling liquid. The cooling liquid can be used to prevent freezing under cold weather and to prevent boiling under high temperature. It is applicable to vehicles running under various temperatures. Furthermore, the cooling liquid contains rust-inhibiting and anticorrosion additives, which offer special protection to the water tank and generator cooling chamber, and avoid cylinder sleeve cavitation and cooling system corrosion.

The freezing points of Weichai Power dedicated cooling liquids shall be -25°C, -35°C, -40°C, etc. Please use Weichai dedicated cooling liquids of appropriate freezing points according to local ambient temperature. The freezing point should be approximately 10°C lower than the local temperature.

Note:

1) The coolant must be checked periodically, and to prevent damage caused by corrosion, it should be replaced in time according to the situation.

2) It is forbidden to use water or cooling liquid of bad quality as coolant for engine.

4.2 Daily Maintenance of Diesel Engine

Every day, before starting the diesel engine, check the external parts of engine, as following:

1) Check cooling liquid level, oil level and fuel level;

2) Check if there is leakage in fuel system, cooling system, lubrication system or on junction surface.

3) Check if connection and fastening of external parts and accessories are in good condition;

4) After start-up of engine.

Check cooling liquid level

Observe the cooling liquid level through glass sight hole, if the coolant is not enough, open the filling port and add the coolant.

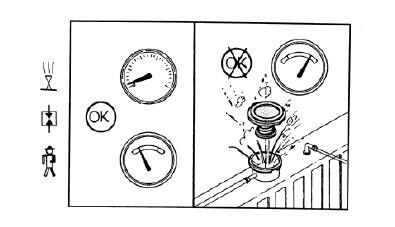

Note: When opening the filling port cover, the air exhaust button must be pressed down first in avoid of hurt by coolant when the diesel engine is in hot state.

Figure 4-1 Explanation graph of notes for water filling port cover when filling in water

Check the oil level

When the oil level is below the lower scale mark of dipstick or above upper scale mark of dipstick, it is not allowed to start the diesel engine.

If check the oil level after shutdown of diesel engine, at least wait for 5min to make the oil has sufficient time to flow back to oil sump.

Check fuel level

Check for “Three Leakages”

No water leakage, air leakage or oil leakage on the vehicle.

Check the belts

Belts are automatically tensioned by belt tensioner, and users check the tightness of belts through pressing the belts by hand.

Check if the sound of engine is normal.

Check if speed and vibration of engine is normal.

Lubricant Replacement of Diesel Engine

Unscrew the oil drain screw plug at bottom of oil sump, drain up the oil and tighten the oil drain screw plug;

Open the oil filling port cover, refill oil through the oil filling port, observe the scale of dipstick until it meets requirements, and then tighten the oil filling port cover.

Replacement of Filter Elements of Oil Cooling and Filtration Module

1) Remove the old oil filter;

2) Fill up the new filter with clean oil;

3) Before assembling the new oil filter, apply oil on the sealing gasket;

4) After the gasket contact with the base, tighten again by 3/4 to 1 round, and make it sealed;

5) Start the diesel engine and check if there is oil leakage.

Replacement of Fuel Filter Element

1) Disassemble the old fuel filter elements;If the water collecting vessel installed on the coarse filter can be used again, please remove the water collecting vessel;

2) Lubricate the seal;

3) Screw up the fuel filter by hand until the seal connect with the connector;

4) Continue to screw the filter by hand until the filter is securely installed (by about 3/4 round);

5) Exhaust the air until no air bubble appears;

6) Conduct leakage test.

Adjustment of valve clearance

Check and adjust the intake and exhaust valve clearance in the following steps.

1) When the diesel engine is at cold state, turn the crankshaft clockwise (in the same direction where the diesel engine rotates) until the pistons of Cylinder 1 and Cylinder 4 reach their TDCs respectively.At this moment, the OT scale mark of crank pulley aligns with the pointer above it.

2) Disassemble the valve rocker arm cover on the cylinder head, and judge if Cylinder 1 or Cylinder 4 is in its compression stroke (There are clearances between air intake and exhaust pipes and rocker arm of cylinders which are in their compression strokes).

Figure 4-5 Adjustment of valve clearance

3) As is shown in Figure 4-5, use a feeler gauge to check the clearance between upper plane of valve and rocker arm of valve.If the clearance is overlarge or oversmall, it is possible to meet the clearance requirements by adjusting the adjusting bolts on the rocker arm.In cold state, clearance of the air intake valve is required to be 0.35mm, and clearance of the air exhaust valve 0.35mm.

4) After check of Cylinder 1 or Cylinder 4, turn the crankshaft clockwise again by 360° so that Cylinder 1 or Cylinder 4 is at TDC of its working stoke, and then check and adjust the rest valves.

Table 4-2 Status of all cylinders in compression stroke

4.3 Maintenance for Long-Term Storage of Diesel Engine

Cleaning of diesel engine; Protection work:

1) If the diesel engine will not be used for a long time, after shutdown of engine,it is required to drain the oil while it is hot.

2) Open the water drain valve, drain the cooling water in water jacket of engine block and water pump shell.

3) Drain the diesel in the fuel tank.

4) Remove the dust on the air filter elements (Paper air filter).Oil bath type air filter elements should be cleaned with diesel or kerosene.

5) Clean the oil sump and oil strainer.

6) Dismantle the air intake pipe, refill 300g of filtered 20# dehydrated oil (namely heat the oil to 110°C~120°C,until all foam disappears), turn the crankshaft so that the oil is evenly attached to the surface of valve, cylinder liner and piston and other parts, and connect the air intake pipe in place.

7) It is required to wipe out the stain, water and dust on external parts of engine and also apply anti-rusting oilto unpainted parts (add butter to dehydrated oil, after dissolved, it is formed by mixing them evenly). Oil shall not be applied to rubber products or plastic products.

8) Use oiled paper to pack and seal the air filter and air exhaust pipe orifice, in avoid of intrusion of dust or dirt.

9) The diesel engine should be placed indoor where is well ventilated, dry and clean, and it is forbidden to place it where there is corrosive chemicals, besides, pay attention to preventing the engine from damp (especially electric system), with above oil sealing method, it can be sealed and stored for three months,when the period expire, repeat above oil sealing method.

Comments